Dyeing Fabric

Dyeing textile involved immersing or dipping a fibre, yarn or fabric in a colour pigment to change its colour. We have been doing this for centuries and will continue to dye fabrics for many centuries to come. Colour is known as a pigment and the way of keeping (fixing) the colour is to use a mordant, a chemical that fixes the dye to help prevent loss of colour when washing or wearing the product. To be successful at dyeing you must:

- Achieve the right colour.

- Make sure the colour is even throughout.

- Make sure the dye does not damage the fibre, yarn, or fabric.

- Make sure you can repeat the process and match the colour.

- Make sure the colour is fixed (often called colourfastness) so it does not run or wash out.

Stages of dye application

When we go to the market we find it is not only fabrics which are dyed but sewing threads and knitting yarns are also available as dyed materials.

1- Chemical Dyeing

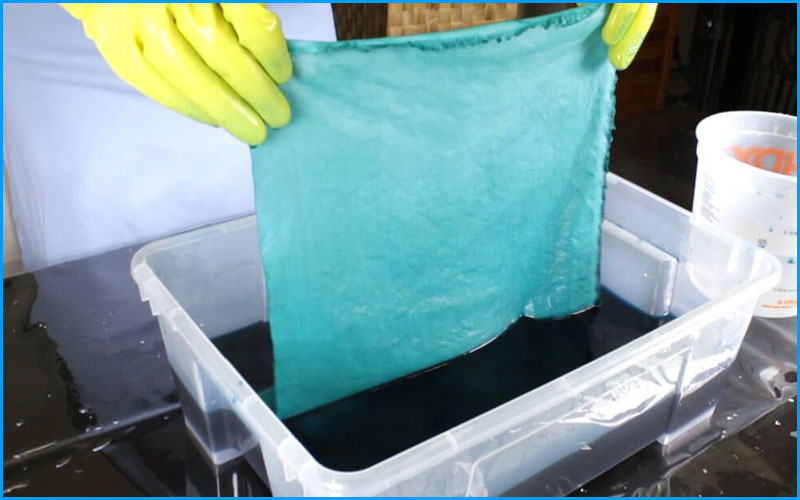

This is the method that uses pigment (chemical dyes with salts added to fix the dye; these can be made up with water. The fibres, yarns or fabric are then immersed in the dye bath until the depth of colour is achieved.

2- Natural Dyeing

Natural and vegetable dyes were the first-known dye pigments and with the move to be more environmentally friendly are becoming popular again. These work best with natural and regenerated fibres and fabrics and require a mordant to fix them to the fibres.

3- Industrial Dyeing

Industrial dyeing can be done at the following stages:

- Fibre Stage.

- Yarn stage.

- Liquid Polymer Stage.

- Fabric stage.

- Garment Dyeing

4- Dip Dyeing

The fabric is dipped but not immersed to take up some dye on only part of the fabric or more depth of colour on part of the fabric; then it may be dipped again to get two or more colours blending together. This can be done in the classroom and achieves a popular patterned effect.

5- Tie Dyeing

Tie-Dyeing, the fabric is wrapped, tied or folded in section to stop the absorption of the dye. The fabric is then put in the dye bath and left for the required time. A multi-coloured effect can be achieved if the fabric is untied after the first colour is set a and the re-tied and redyed in the second colour.

Research

Wool consistently developed the most intense colors with all of the dyes. Nylon, cotton, and acetate were also relatively easy to dye. Polyester was the most difficult fabric to dye.

For example, polyester does not take dye easily, so materials are added to the dye bath to help the fibers pick up the dye in a uniform manner. Various methods and techniques of dye application. ... Some dyes are not colorfast to sunlight. Fumes and ozone may cause a change in color of some dyed fabrics.

The dyeing of cloth after it is being woven or knitted is known as piece dyeing. It is the most common method of dyeing used. The various methods used for this type of dyeing include jet dyeing. Jig dyeing, pad dyeing and beam dyeing.